The Sky is the Limit

October 13, 2021

Like us, Spirit AeroSystems, a global leader in aerostructures manufacturing, calls Wichita home. Our long history together started back in 2002 when we designed a simple air handling unit safety platform for them. Before long, our relationship developed into a master service agreement with Spirit assigning MKEC on average more than 30 projects a year.

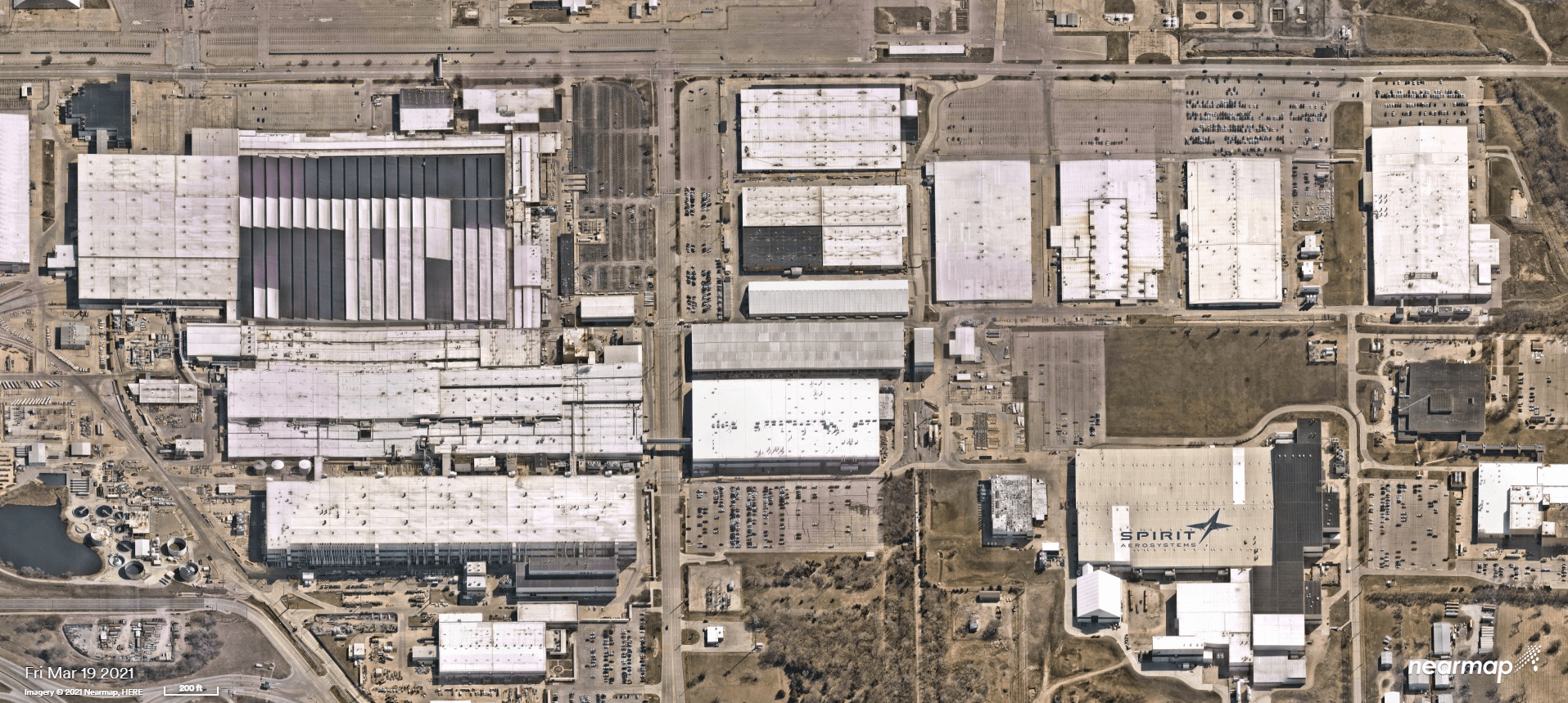

Those projects range from new buildings with everything from production to composite cleanrooms. We have also designed additions to existing buildings and made modifications to the MEP systems as well as installing and relocating the massive tools used to build aluminum and composite aircraft parts. Along with design duties, we have also provided utility mapping, system dynamic modeling and site scanning services.

There isn’t a square foot of Spirit’s campus that our experts from each of our service areas haven’t touched. We’ve contributed to full plant utility studies, process evaluations, and the evaluations of every building to ensure peak performance of all mechanical, electrical and chemical components.

Over the years, Spirit has continued to rely on our engineering services because of our diverse background of completed projects, our employees’ experience and expertise, and our dedication to providing the absolute best design that meets or exceeds Spirit’s requirements, within a given budget.

Several key projects we helped design have played a critical role in helping Spirit ramp up its composite production capabilities. One was the design of a massive autoclave – a 120-foot-long pressure chamber that cures composite material – that was, at the time, one of the largest in the world. We designed the structure supports for the autoclave structure and the automated door. Since then, we contributed to a newer, even larger autoclave, which surpassed the last one by 10 feet. Mechanically speaking, we designed the tower water system, natural gas, vacuum, and nitrogen systems. The electrical work we performed included the design of the data, controls, fire alarm, lighting, and power systems. Another one was a cleanroom building expansion to provide Spirit with more square footage of controlled environment space for fabrication of composites.

As travel rebounds after the pandemic, passengers will return to the skies. Airplane orders have begun to rise in 2021 after declining in nearly all of 2020, in anticipation of a return to travel. As Spirit gears up to support the renewed demand, we are committed to delivering engineering solutions that underpin their high standards for efficiency and quality.