Fitting the Pieces Together to Improve Wichita’s Water Treatment

January 19, 2024

The giant Star Wars Millennium Falcon Lego set has 7,541 pieces. The finished spaceship is huge, measuring nearly 2 feet wide and 3 feet long. That’s a big ship, but to put it together, you start with two pieces. Then you add another one and another one and another one until eventually all 7,541 of those pieces are locked together to create one fantastic Lego model.

Our latest project for the city of Wichita is a lot like that Millenium Falcon (although we admit perhaps not quite as cool as a ship that can do the Kessel Run in less than 12 parsecs). Designing and building Wichita’s new water treatment plant required a lot of different pieces to come together to create a state-of-the-art water treatment facility.

Putting the pieces together

The City of Wichita draws its water from wells and nearby Cheney Lake. However, the existing water treatment plant can only treat the water as long as it is a blend from those two sources, which means the city could suffer water shortages if one of the two sources of supply become unavailable. Despite studies in the past about whether to retrofit the old plant or build a new one, it wasn’t until new federal funding became available that a new $500 million water treatment plant could become a reality.

“Burns & McDonnell is leading the design effort,” said Keith Ayotte, senior project manager, municipal services, for MKEC. “They formed a company called Wichita Water Partners. The project is a design-build that involves most of the major engineering firms and contractors in Wichita that all joined forces because of the construction size.”

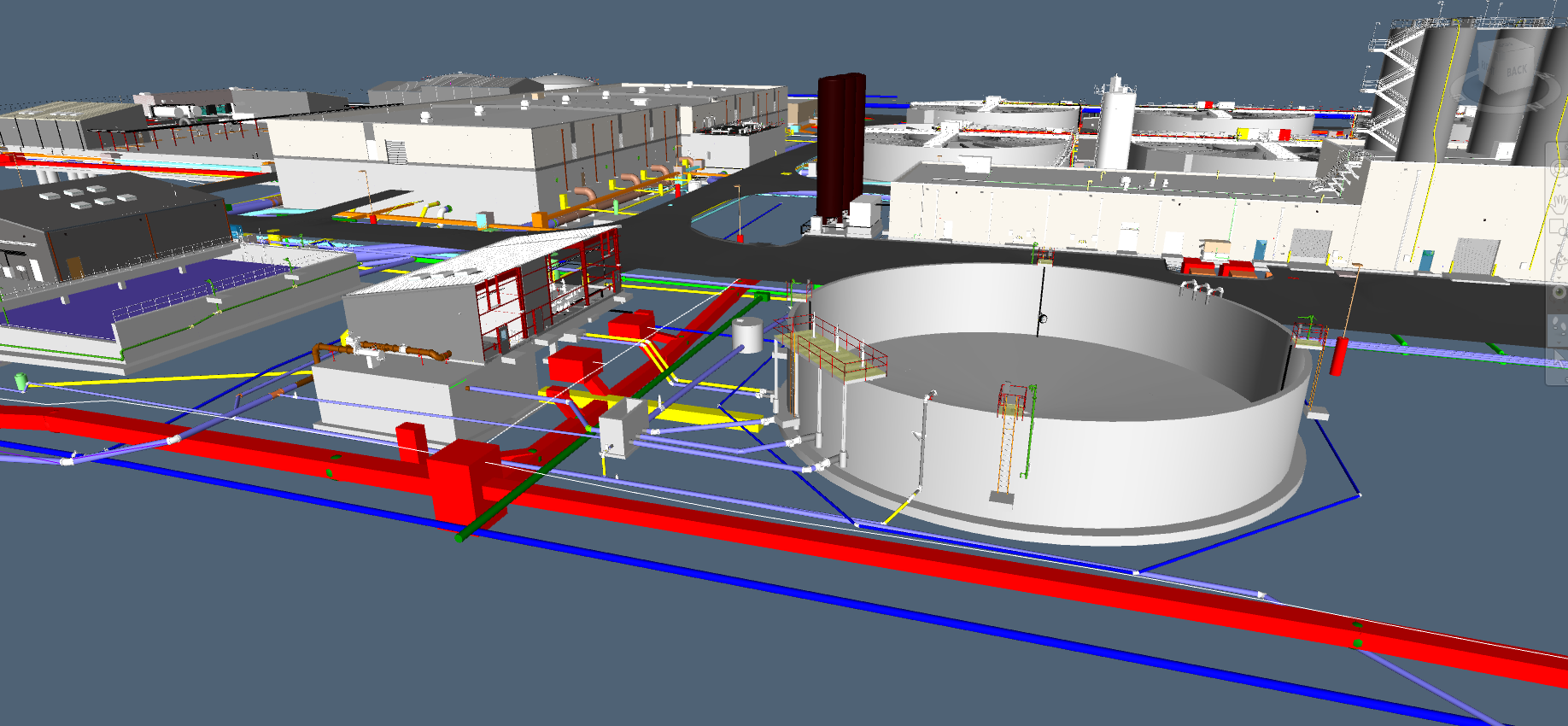

Design on the new plant started in 2019, and the opening is still a year away, in 2025. When finished, the plant will be able to treat up to 120 million gallons of water a day and will have fully redundant systems to prevent water outages.

Because the scope of the project is so large, more than a dozen engineering and construction firms are working together to complete it. MKEC team members from civil, electrical, mechanical, process, and instrumentation and controls worked on multiple pieces of the project, including residuals handling, a new maintenance building, a 66” pipeline that bypasses water around the current water treatment plant, a fiber optic system that provides city staff communication capability with the new treatment plant, and on-site instrumentation and controls systems.

Coordinating the work of more than a dozen engineering and construction firms required a structured communication plan and cloud-based collaboration software was part of that plan.

“There were a lot of situations where the items we designed connected to pieces other people were designing, making sure changes were communicated was really important.”

Keith Ayotte, PE, Senior Project Manager

“There were a lot of situations where the items we designed connected to pieces other people were designing,” Ayotte said. “One change could have affected three other firms. Making sure changes were communicated was really important.”

“MKEC probably participated in a minimum of four meetings a week for year,” said Mark Buckingham, senior project manager. “Burns & McDonnell had someone who was charged with managing MKEC and one other design firm. We had two firms under us. We worked at establishing good working relationships with people we knew we were going to be working with consistently for the next couple of years.”

“We worked at establishing good working relationships with people we knew we were going to be working with consistently for the next couple of years.”

Mark Buckingham, PE, LEEED AP, Senior Project Manager

Focusing on our strengths

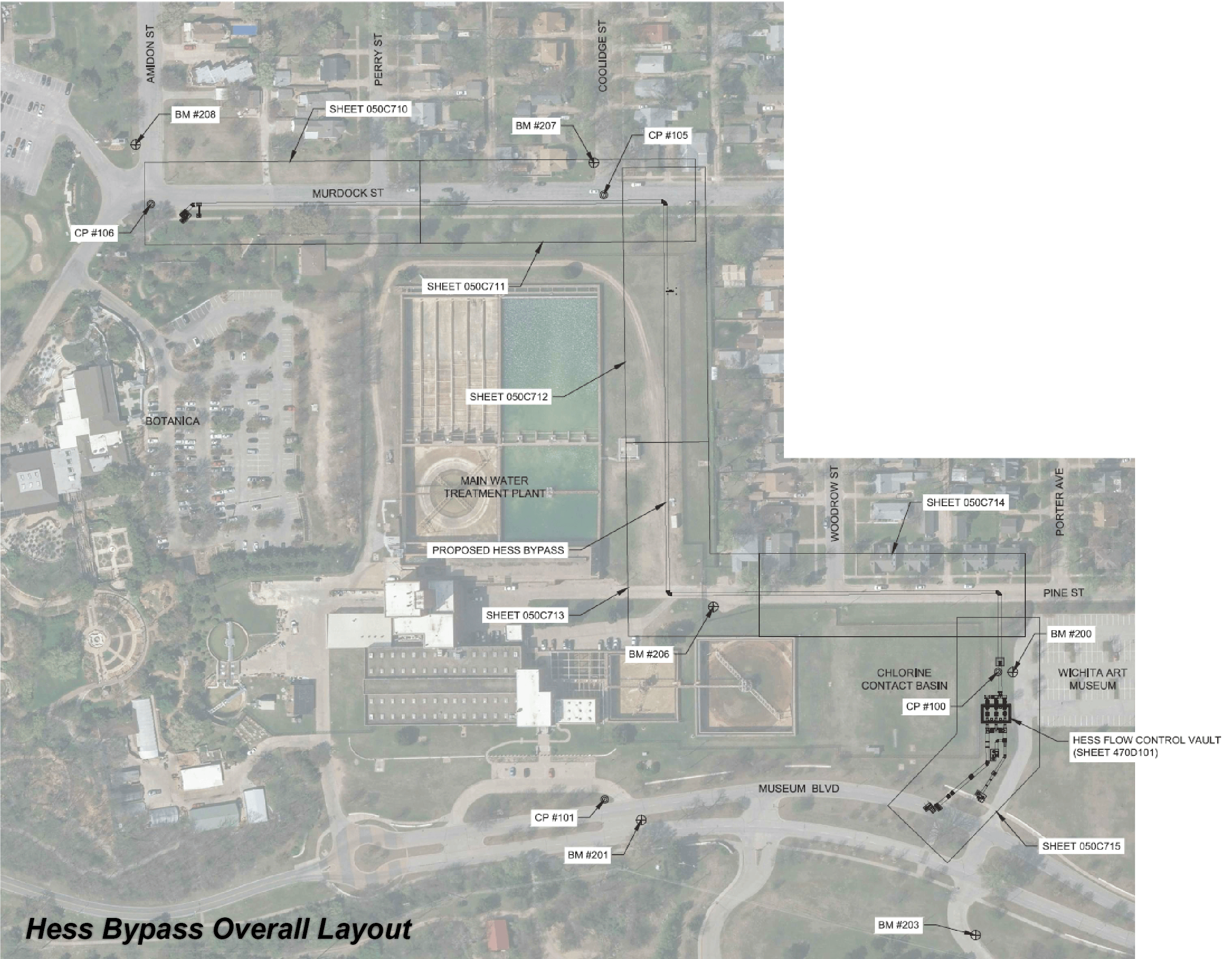

When pursuing the project, we focused on MKEC’s strengths. Over the years, we had done some work at the existing water treatment plant. The new plant will use the existing clear wells at the existing water treatment plant, which means water needs to travel from the new plant back to the old one. With our knowledge of the existing water treatment plant, we knew this would be a good piece of the project for us.

“We designed a 66-inch pipeline, the bypass line, down at the existing plant,” Buckingham said. “The city is going to treat the water at the new location, send it toward the existing plant in large pipelines across the city, so it can be stored in clear wells.”

We also focused on incorporating the new plant into the City’s existing communication and controls infrastructure.

“Another major part of it is that we designed a fiber optic system across the city that links City Hall and the existing plant and the new plant,” Buckingham said. “Those three points are connected by redundant fiber optic lines.”

In addition, the instrumentation and control (I&C) team has been involved in the project from the beginning.

“They’ve been involved in the design process and throughout construction and into what is called commissioning and start-up,” Buckingham said. “Commissioning is just an array of checks that are done over a building or a process or a piece of equipment to make sure it’s ready to go. Start-up is just what it sounds like. Flood the pump, fill the pipe. See what goes wrong or right. Fix what went wrong. Then move down the line. Our I&C team will be there for commissioning and start-up. They also have to make sure our instruments read the temperature or the flow correctly and send that back to the operators at the control center.”

Before the water treatment plant project, MKEC had done several other smaller instrumentation and control projects for the city, which set us up to be a perfect fit for this larger job.

“MKEC is also largely involved with the I&C work,” Ayotte said. “Being an engineering firm that can also provide those services is unique. Long after the plant’s operational, this I&C and control work will continue. Thousands of instruments and controls. We’re right next door to the city. If they have issues and need tweaks, we’re right there.”

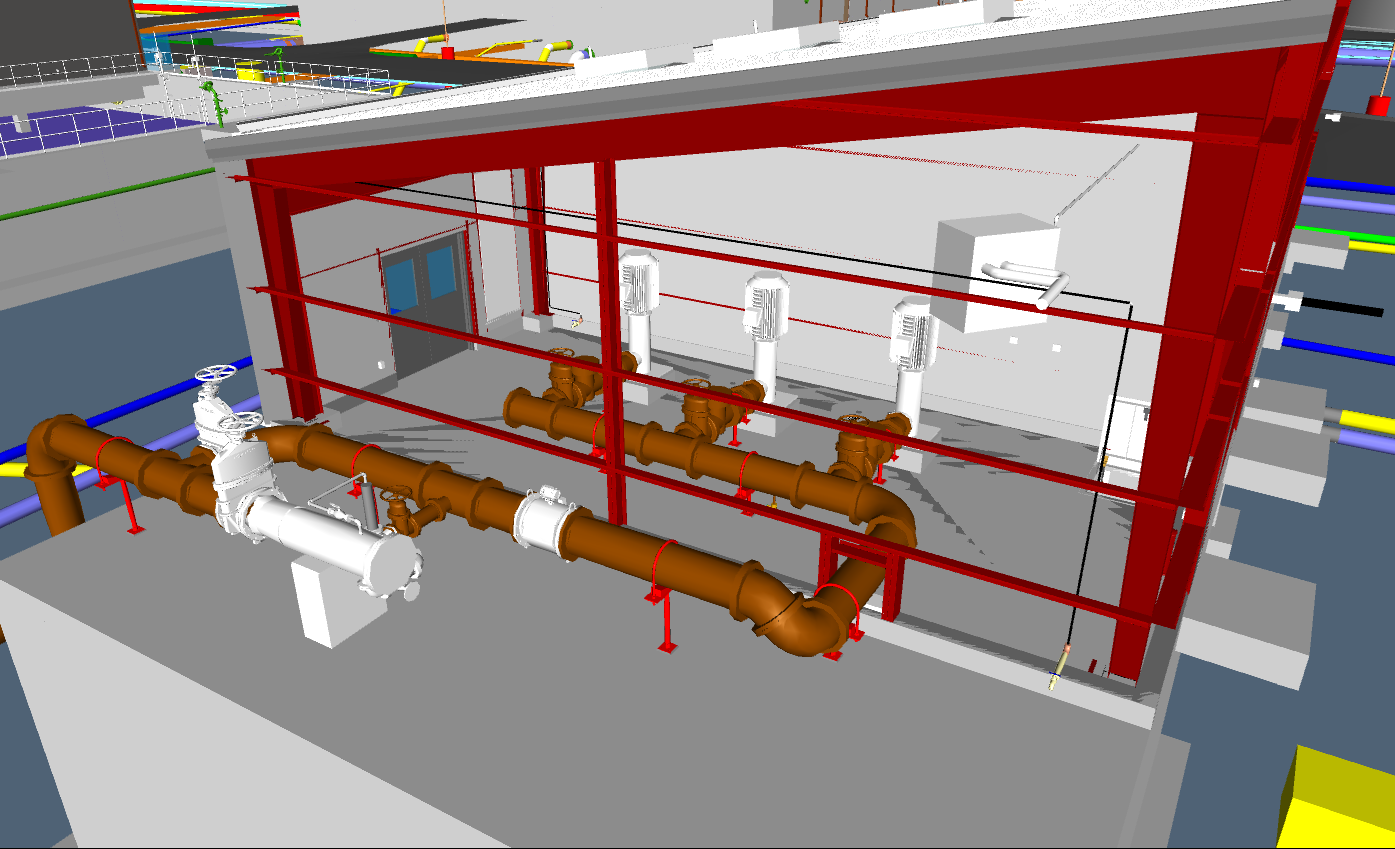

MKEC also designed the residuals system, a maintenance building, and the sludge and basin drain disposal pump station building on the treatment plant site.

Being a good neighbor

In a project of this size that requires creating connections between different facilities, a certain level of disruption to neighborhoods and businesses is inevitable. As part of our design, we needed to put the 66-inch line onto the existing water treatment plant site, which required tearing up some of the older streets in the city in and around residential neighborhoods.

While this is an important project for the city, the people in those neighborhoods needed to be able to live their lives while the construction is ongoing, which is why we always do our best to create designs that take everyone’s needs into account.

“We were connecting to an 84-inch pipe,” Buckingham said. “There was no way to do it without tearing up the street. There’s not a lot of room.”

As the water treatment plant project enters its final phase, we and the people of Wichita can finally see what results when all the pieces fit into the right place. By the end of 2024, Wichita should have a water treatment facility that will help the city launch into the future.